As many 3d printer enthusiastic learns that the build plate is very an important element for the first layer of the model you build, we know that there are several kinds of build plate that you can select with: simple glass bed( basically you have to use it with some glue or texture paper.); tempered glass bed; flexible build plate; PEI build plate.

Today we are going to talk about how you can use different build plate-like PEI as a covering for the bed, and it can help with adhesion and easy to remove the model.

What is PEI sheet?

Polyetherimide, a lot more frequently understood in its abbreviated form PEI, is a "reasonably maintenance-free" build surface that can be made use of for all types of filament on a warmed or unheated print bed. It doesn't need any type of added adhesives such as adhesive or tape. It basically with a PEI platform and a soft magnetic sticker with stronger adhesion, easy to use and replace.

PEI requires "no-surface-prep" before use, which makes it very practical to work with. The guidelines for usage also suggest that utilizing a PEI sheet on your print bed will eliminate the requirement for a plethora or brim, as parts are anticipated to adhere directly to the surface area without issue.

PEI has excellent mechanical residential properties, radiation resistance, high as well as low-temperature resistance, high-temperature stability, and high wear resistance in addition to great fire retardancy, chemical resistance, and also electric insulation qualities. Not to mention ... it is available in numerous shades too!

How to Use the PEI build plate?

- First of all, prior to you including the PEI sheet, keep in mind to get rid of the initial glass or sticker label on the lightweight aluminum plate. In some cases, you have to establish the bed temperature as it called for, and also wait till it reaches the temperature level, start in one edge as well as peel it off.

- At this point, you need to have to analyze the print surface. If the remaining adhesive is simply a thin attire covering instead of unequal balls, you can apply the brand-new self-adhesive sheet directly over the top. Otherwise, you need to level some denatured alcohol or isopropyl alcohol, using a scraper to give the warmed bed a tidy smooth finish.

- It's very important that you scratch any type of bubbles or swellings out as you connect the sheet to your print bed. Make certain to take it steady and also apply small portions at once, beginning along one side and also moving throughout the bed. Once the whole sheet is installed in the system, make certain no bubbles are appearing externally. You can use your printer's scraper to smooth every little thing out until the PEI sheet is as smooth as possible.

- After the PEI sheet is applied, then put with the other pcs of the build plate, now you can start the bed leveling and model creating.

PEI Build Plate Advantages:

1.It is readily available, relatively inexpensive to acquire, and easy to use and get rid of.

2. It can provide superb attachment for a published thing, removing the need for tapes and adhesives.

3. It supplies a smooth surface area coating (while it remains undamaged).

4. It gives excellent thermal conductivity for a warmed bed.

PEI Build Plate Disadvantages:

1.It is relatively soft and can be damaged by a badly changed print bed or excessive scratching.

2.It can adhere really highly to a published product, taking the chance of damage to both the bed and the thing as well as taking a great deal of initiative to eliminate the printed product.

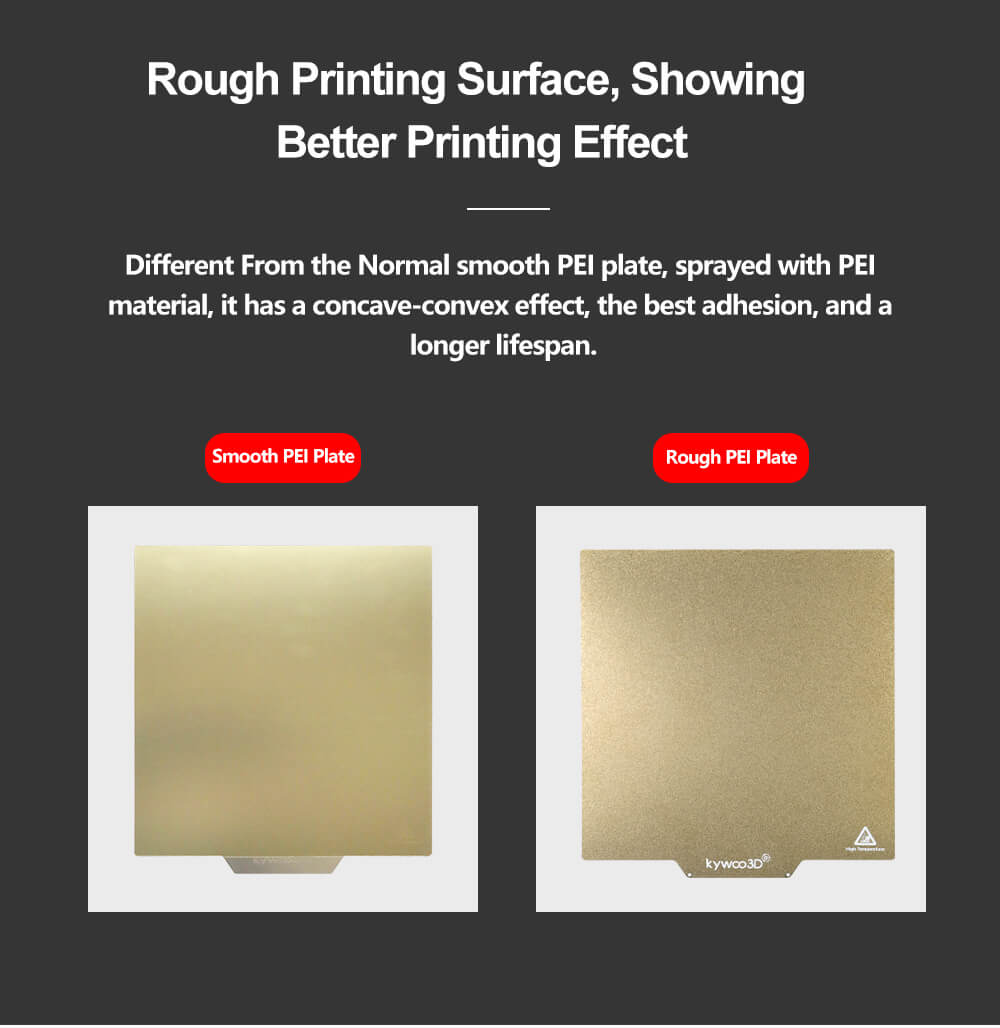

Differences between PEI Smooth Surface and PEI Gold Frosted Surface

There are two kinds of PEI surface, if print with the PEI smooth, the model bottom comes out with flatness, it will be more suitable for small creations. If print with big models, you can have a try the PEI gold frosted surface.

The main difference between these two kinds of PEI build plate is the build plate surface, but from what I check and tested, the one with a textured surface performs much better than the smoother one. And it can better print with filaments such as PETG, ABS, and Nylon.

Currently, we have two kinds of PEI build plate comes out, from what we tested, the model comes out with this kind of PEI build plate with even a better surface. Below are some features of the PEI gold frosted surface.

Kywoo PEI Gold Frosted Surface Features

1.No Deformation at 200℃

Made of premium material, the original PEI powder coating with heat resistance, the hardened steel spring plate can accept 200℃, but no deformation.

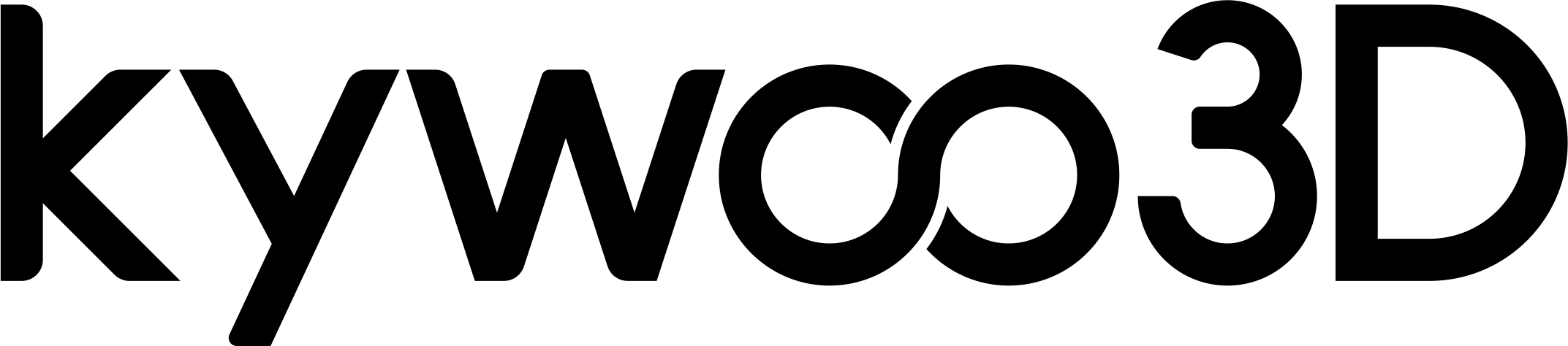

2.Strong Magnetic Force and Adhesion

Composite magnetic material without demagnetization is easy to hang and pick up. Gold texture PEI printing plate + Flexible Magnet platform sticker. 2 in 1 kit make the PEI print bed with stronger adhesion, easy to use and replace.

3.Flame Retarsant and Heat Reaistant

PC belongs to the Flexible magnet, with flame-retardant, wear-resistant, oxidation-resistant, low forming shrinkage, and heat resistance without demagnetization.

4.Rough Printing Surface, Showing Better Printing Effect

Different From the Normal smooth PEI plate, sprayed with PEI material, it has a concave-convex effect, the best adhesion, and a longer lifespan.

5.No Model Warp Anymore

There is a good combination between hot-melt material and printing layer, which reduces the deformation caused by shrinkage and avoids warping.

Mostly I use PEI sheet on the our 3d printers, it with better adhersion and easier to remove the models compare to tempered glass and flexible build plate.

What is the differences among PEI sheet, magnetic build plate and tempered glass bed, read the related blog here: 3d printer build plate comparision